Ultrawear®

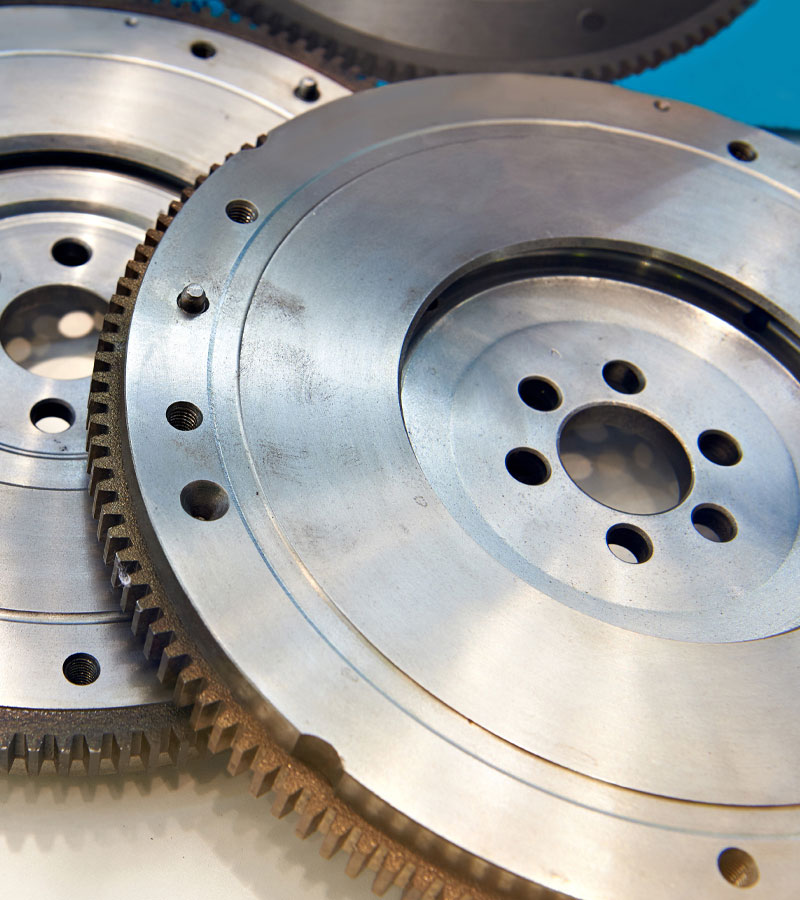

This 4140 alloy steel hardening solution increases wear resistance, hardness, and fatigue strength for gears, dies, and high-load applications.

This 4140 alloy steel hardening solution increases wear resistance, hardness, and fatigue strength for gears, dies, and high-load applications.

Nanowear is an exceptional ferritic nitrocarburizing (FNC) heat treatment, delivering a durable compound layer and diffusion zone.

Across industries, equipment and components face constant threats from corrosion, fatigue, galling, and abrasion. Left untreated, these conditions shorten part life, increase maintenance costs, and lead to unplanned downtime. Woodworth Heat Treating combats these risks with Nanowear™ and Ultrawear™: our proprietary thermal chemical diffusion processes.

Our reliable heat treatment for 4140 steel and stainless steel delivers durability where it matters most. From providing FNC for automotive components to surface hardening stainless steel parts for energy and marine applications, we extend the service life of critical assets.

Get confidence in the performance and consistency of your components when you request a quote today.

For All Manufacturers

In Michigan and across North America, OEMs and suppliers depend on us for AISI 4140 heat treat services, 4140 crankshaft heat treatment, and FNC for automotive components. We help extend part life, reduce warranty costs, and increase throughput.

For Defense Applications

Our ISO certified heat treating processes, including hardening for bolts and other stainless steel parts, meet the exacting demands of defense contractors who can’t compromise on quality.

For All Sources of Power

Oil and gas pipelines, renewable energy systems, and more benefit from gas ferritic nitrocarburizing and stainless steel hardening treatments that combat corrosion, fatigue, and galling in the most extreme environments.

For Any Application

Critical fastening parts demand resilience. With hardening for stainless steel screws, commercial FNC processing for bolts, and complete heat treating for fasteners, we deliver reliable strength and fatigue resistance.

For All Materials

We specialize in 4140 steel heat treatment and thermochemical surface treatment for mining components exposed to punishing wear and corrosive chemicals.

For Tough Environments

Marine assemblies face relentless saltwater and pressure. With advanced hardening for stainless steel parts, our processes offer unmatched corrosion protection and extended service life in any conditions.

At Woodworth, we combine nearly 60 years of metallurgical expertise with flexible, customer-first service. When you partner with us, you gain:

From our start in Hazel Park, MI, in 1965 to today’s multi-facility operation, Woodworth has grown into a trusted provider of commercial heat treating near Detroit and across North America.

We operate in Flint, Homer, Pontiac, and Puebla, Mexico, processing more than 2.2 million pounds daily with advanced atmosphere-controlled furnaces. Whether you need automotive heat treating services, stainless steel hardening for mining parts, or any number of other applications, our services consistently help OEMs and suppliers reduce costs, increase durability, and improve performance.

Yes. Our commercial FNC processing delivers consistent results for high-volume parts like bolts, screws, and fasteners. This process improves surface hardness, wear resistance, and fatigue life, making it ideal for manufacturers who need reliable performance at scale.

Yes. Woodworth is certified by IATF, CQI-9, and NSF for both industry and public health standards. Our most notable certification is our IATF 16949:2016 certification, which is the International Standard for Automotive Quality Management Syste

IATF 16949:2016 emphasizes the development of a process-oriented quality management system providing for continual improvement, defect prevention, and the reduction of variation and waste in the supply chain. Contact us to learn more about our certifications.

Our heat treatments can be applied to:

If you don’t see what you need on the list, contact us to request a quote. We’d be happy to help you find the right heat treatment for your product.

Our FNC heat treatment uses proprietary furnace atmospheres and gas flows for uniform coverage, even on complex geometries. By creating an iron-nitride compound layer and a carbon-nitrogen diffusion zone, we improve abrasion resistance, fatigue life, and corrosion protection.

To learn more about our process, visit our website or request a quote.

Every hour of downtime costs money. Protect your parts and improve performance with proven heat treatment services. Fill out the form below or call us at (810) 820-6780.